- COMPUTERIZED MAINTENANCE MANAGEMENT SYSTEM MAXIMO MANUAL

- COMPUTERIZED MAINTENANCE MANAGEMENT SYSTEM MAXIMO SOFTWARE

The following are the main benefits of a CMMS. Its primary objective is to add value to an organization's maintenance program.

COMPUTERIZED MAINTENANCE MANAGEMENT SYSTEM MAXIMO SOFTWARE

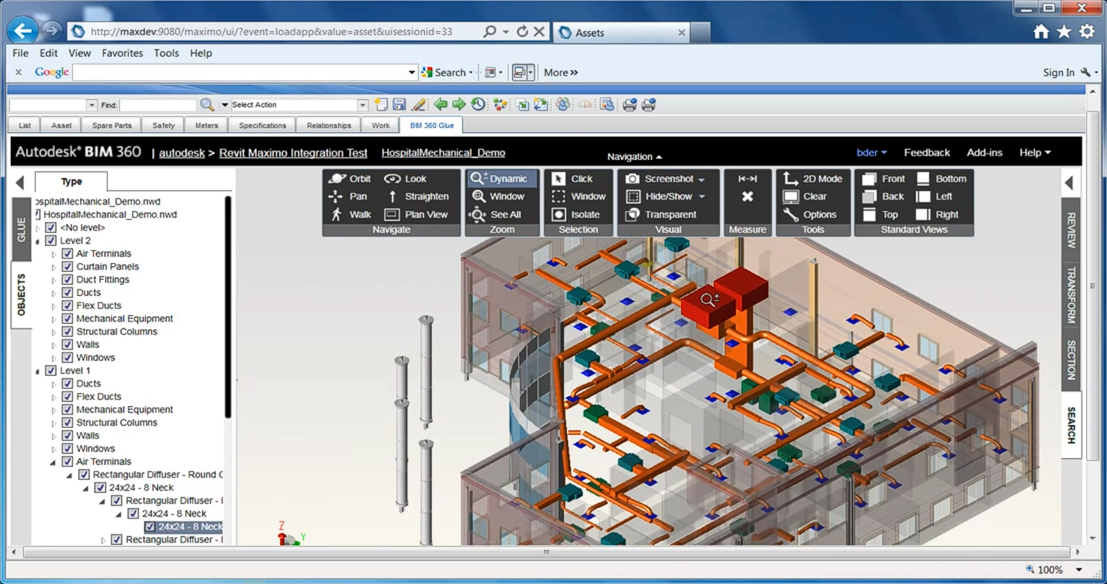

This software is easy to use and features an innovative design that enables companies to facilitate their interventions. The industry 4.0 computerized maintenance system provides the most efficient maintenance management tools. The system is also heavy to parameter and not able to perform beneficial analysis. However, the industry 1.0 management system is difficult to use and doesn't feature a user-friendly interface. This management system enables a team to manage maintenance operations, tasks, spare parts, intervention requests, and other work order management. The industry 1.0 CMMS software is a management system of an older generation. Other information that was not included in these work orders was the specific equipment being maintained and the name of the individual who completed the work order. Unlike today when CMMS provide the date and time of work orders, this information was not available back then. In the '80s, maintenance operations were recorded on paper and included a brief summary of the work order. Although paper maintenance management provides more consistency than ground zero, asset management software was not available. The 1980s' Paper Maintenance Evolutionĭuring the 1980s, paper was the primary maintenance component. On top of these issues, spare parts were not organized, and there wasn't a cloud-based system to control the stock. Because of these facts, preventive maintenance routines were not implemented, and specific regulations were not followed. In this situation, companies didn't know what was going on within their business, and there was no information available if a breakdown occurred or other maintenance malfunctions happened. Although organizations appreciated these new advancements, the problem was the maintenance traceability available on Excel, paper, and asset management software.

In 2018, many advancements that included IoT and sensor data were accepted, but many companies were failing to implement various maintenance management techniques. Let one of our CMMS expert talk to you to learn more about CONSYST CMMS Solutions.The following is a brief history of CMMS. We help our clients to optimize the use of their assets and reach cost effectiveness as Availability, Performance and longevity are our primary motto to enhance the performance.Our customers report measurable improvements and we have achieved a high rate of client satisfaction. Since its inception, CONSYST has been instrumental in providing strategic solutions that changed the face of maintenance and facilities management. Predictive & Periodic Maintenance Management.Reduces Downtime & Improves Asset Life: Proper Maintenance at Right Time avoids unexpected breakdowns.Digitization makes access to historical reports quick and easy.

COMPUTERIZED MAINTENANCE MANAGEMENT SYSTEM MAXIMO MANUAL

0 kommentar(er)

0 kommentar(er)